Stud and nut conversion for 5 stud wheels (20 supplied)

Stud and nut conversion for 5 stud wheels (20 supplied)

M12 x 1.5mm / 68mm / 68mm

Brake-Shop Unit 2 Foothold Enterprise Village

SA15 2DS

Brake-Shop Unit 2 Foothold Enterprise Village

Llanelli SA15 2DS

United Kingdom

Brake Shop Stud & Nut Kit For ALL 5 stud vehicles

*If you are unsure if this is correct please leave a note with your vehicle model or registration number and we will make sure the correct kit is sent*

Remove and install your wheels at the track all the time? Then you’ll know how frustrating the factory wheel bolts can be. Lining up the bolt holes, bashing the wheel against your beautiful brakes calipers, then cross-threading the bolts at the same time. All while balancing the weight of the wheel. Our Stud & Nut kit gives a stronger fixing method than using the original wheel bolts. Plus they’re a much quicker method to swap wheels for motorsport / track use as well.

- Converting your car to our Stud & Nut Kit is a simple, reversible upgrade that will speed up your wheel changes.

- Our Stud & Nut Kit also allow for the safe use of different spacer size setups without the risk of running out of bolt threads.

- Beautiful midnight-black finish on the nuts will smarten up your car’s looks as well as its practicality.

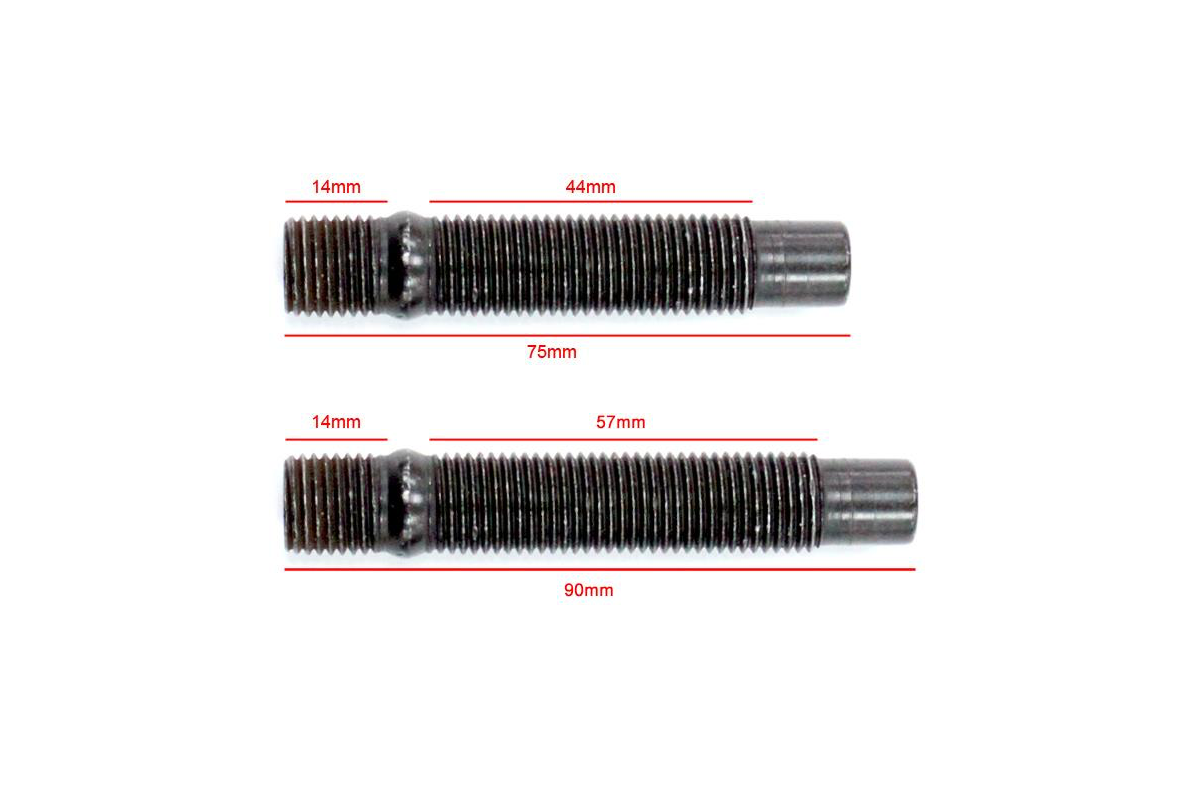

Which Stud Lengths do I need?

- If your vehicle has No wheel spacers, you can use 68mm Studs

- If your vehicle has up to 5mm wheel spacers, You need the 75mm Studs

- If your vehicle has 6-10mm Wheel Spacers installed, You need the 82mm Studs.

- If your vehicle has 11-20mm Wheel Spacers installed, You need the 90mm Studs.

- If your vehicle has different spacers front to rear order the correct size you need to suit

Stronger Fixing

High Tensile Steel Motorsport Studs and tapered Wheel Nuts exceed the strength of the factory bolts for ultimate strength and safety.

Quick Wheel Changes

Stud and Nut kits are suited to any car that sees track use with regular wheel swaps. The studs really help to speed things up when you are trackside.

Fitting Instructions

Professional installation of this product is recommended.

Tools & Consumables

- Thread Chasing Tool (size dependant on your vehicle)

- Penetrating Oil (such as WD-40)

- Brake Cleaner

- Clean Cloths

- Wire Brush

- Thread Lock

- Correctly Calibrated Torque Wrench and Suitable Sockets

Installation

Check hub face and threaded holes for any rust or imperfections, clean off all corrosion from hub face/ ring using your wire brush, clean/ chase the threads using brake cleaner, thread chasing tool and penetrating oil. Once the threads have been chased, use brake cleaner and a clean cloth to ensure NO contaminants remain/ brake cleaner runs clear out of the threads.

Apply brake cleaner to each new stud and wipe with a clean cloth. Leave brake cleaner to evaporate (around 1 minute).

To test, manually thread one stud into the hub using the short end of the threads. Verify that the stud does not prematurely bottom out inside the hub. If you have any concerns about this, use a pen or a thin tool to measure the usable depth of the stud hole. Ensure that the depth is not less than the length of the stud you are installing. There may be a portion of a broken wheel bolt or other debris trapped inside. Perform this process for each stud hole.

Run a small amount of thread lock on the tip of the stud and approximately 5mm down the smaller threaded portion of the first stud. Only a small amount of thread lock is required on the section of the stud that will be installed in to the hub. Don't use excess amount.

Hand tighten a stud into the hub. Thread one nut halfway down the stud, ensuring there is room for another nut. Now thread the second nut, butting up against the first nut with the cones facing each other. Use the correct socket to tighten the two nuts together. Now use a torque wrench on the second nut to torque the stud to 32Nm. Perform this process for each stud.

Note the thread lock will take approximately 1 hour to set and 24 hours to fully cure.

Install the wheel, no consumables need to be used. Tighten wheels in a star-pattern (the nut diagonally opposite each time). Lower the vehicle and torque each nut in the star-pattern, to 122Nm. Recheck after 100 miles/ after returning to pits from track.

YOU WILL GET 20 STUDS AND BLACK NUTS WITH THIS KIT